Now that Architects & Engineers for 9/11 Truth is closing in on 3,000 architect and engineer petition signers, we are taking this opportunity to introduce our readers to some of the individuals who make up the ranks of our building and technical professionals.

Below are profiles of three engineers who have added their name to the petition. In so doing, they lend their expertise and credentials to our call for a new investigation into the destruction of the World Trade Center Twin Towers and Building 7 on September 11, 2001.

After you read their stories, let us know if you'd like to meet more of our engineers and architects!

Anthony Lusich, F.ASCE, Geotechnical Engineer

Anthony Lusich studied civil engineering at the University of Southern California, earning his Bachelor of Science degree in 1975. Subsequently specializing in geotechnical engineering, he has centered his career on the design and building of structural foundations in the Bakersfield area of California. Now a senior engineer at Kleinfelder, a civil engineering firm in San Diego, Lusich has facilitated residential, commercial, and institutional construction and has also contributed to various transportation, oilfield, and water-related projects.

Lusich is active in the engineering and local business communities. For the last eight or nine years, he has served as Kern County Chapter president of the American Council of Engineering Companies; as a member of the board of directors of the Kern Transportation Foundation; as treasurer of the Kern County Branch of the American Public Works Association; and as a member of the Government Review Council of the Greater Bakersfield Chamber of Commerce. He is an affiliate of the American Institute of Architects (AIA) and has been a fellow of the American Society of Civil Engineers (ASCE) for over 40 years.

On the morning of September 11, 2001, Lusich observed the North and South towers of the World Trade Center collapse while watching news coverage of the jet impacts on television. He remembers: “I was definitely not expecting either collapse. While watching the towers burn, I had no educated suspicion that the buildings would inevitably fall.”

Asked if he recalls whether the collapses seemed plausible at the time, Lusich admits that his “consternation precluded any thoughts either way.” Such a reaction is unsurprising, given that most people glued to their TV sets that morning — building and technical professionals included — were in a state of shock, recalls AE911Truth founder Richard Gage.

As the years elapsed and Lusich's memories of that fateful day faded, he came to accept the findings of the initial investigations. But in the last two years, he began to doubt the official narrative. Prompted by his daughter, he decided to take a look at the investigative work of Architects and Engineers for 9/11 Truth.

After carefully considering AE911Truth's evidence, which overwhelmingly disproves the official account, Lusich joined the building and technical professionals — at the end of November standing at 2,950 and counting — who are petitioning for a new investigation. Now that he's a signatory, he has discussed his impressions of the WTC evidence with friends and acquaintances and has encouraged them to reconsider their conclusions.

When asked if he believes that the American public needs to push for independent research, his response is an emphatic “Yes!” Lusich also recommends that all Americans contact their congressional representatives to voice their view that a new WTC investigation is needed.

One way that AE911Truth supporters can reach out to their members of Congress is through our online letter generator, which encourages representatives to support the new Bobby McIlvaine World Trade Center Investigation Act.

Bruce Caswell, Chemical Engineer

Bruce Caswell earned advanced degrees in chemical engineering and has worked as an engineer for major players in the chemical industry, including DuPont and Dow. He also spent many years teaching at the university level. His expertise on the combustibility of materials led him to testify on the subject in court trials on two occasions.

As he watched the attacks of September 11th unfold on live television, Caswell was struck by how unlikely it was that two 110-story steel-framed office buildings could be reduced to concrete powder and steel wreckage from ordinary fires started by burning jet fuel.

Caswell doesn’t buy the official narrative that would have us believe that the Twin Towers were reduced to concrete powder and steel — in under 12 seconds, no less.

Caswell doesn’t buy the official narrative that would have us believe that the Twin Towers were reduced to concrete powder and steel — in under 12 seconds, no less.

“There was only a small amount of flammable material in the buildings, such as paperwork in file cabinets,” says the now-retired engineer. “The rest of the buildings were composed primarily of concrete, steel, gypsum, and glass, which are not flammable at all under any circumstances.”

“Jet fuel,” Caswell adds, “has a flash point of only about 100°F. It burns with a flame temperature of from 600°F to 1,500°F, depending on which specs you read. However, steel doesn’t melt until 2,700°F. Therefore, there was zero chance that burning jet fuel or the ensuing office fires melted the steel structural beams. The jet fuel, if ignited, would simply burn itself out.”

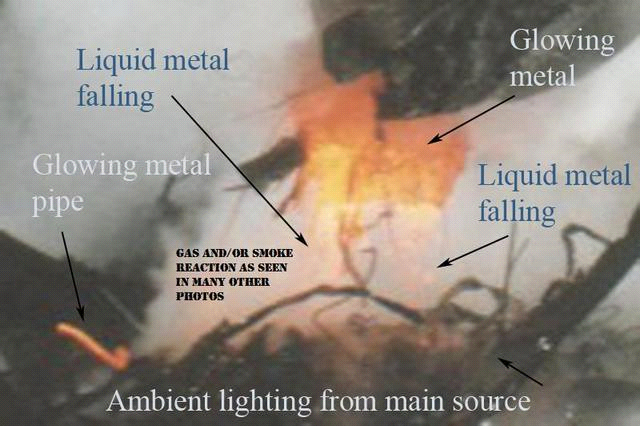

But, as many still photos and videos prove, we did see melted steel. Why? To understand that phenomenon, readers can watch the AE911Truth documentary 9/11: Explosive Evidence — Experts Speak Out.

When asked about the third tower — World Trade Center Building 7 — that collapsed on 9/11, Caswell admits he hadn’t heard about it until several years after the event. Realizing that WTC 7 wasn't hit by a plane, he began researching the subject. One fact that especially interested him was that Barry Jennings, the deputy director of the Emergency Services Department for the New York City Housing Authority, was in WTC 7 on the morning of September 11th, just hours before it collapsed, and had reported an explosion when he reached the 6th floor.

While the officially sanctioned research arm of the U.S. Commerce Department — the National Institute of Standards and Technology (NIST) — has denied the presence of molten steel at the WTC site in the aftermath of 9/11, video evidence and eyewitnesses testimony tell otherwise, Caswell notes.

Chemical engineers like Bruce Caswell acknowledge that jet fuel cannot do this. So what can?

Chemical engineers like Bruce Caswell acknowledge that jet fuel cannot do this. So what can?

“No ordinary combustion process reaches temperatures of this high a range,” says Caswell. “The documented melting of steel was obviously caused by a thermite reaction, which can reach temperatures of around 4,000°F.”

Thermite is a mixture of aluminum and iron oxide powders. It is used most commonly in welding applications. In 2009, an independent team of scientists, led by chemistry professor Niels Harrit in Copenhagen, published a paper documenting the discovery of the chemical signature of nano-thermite in World Trade Center dust. Nano-thermite is a high-tech form of the incendiary thermite, capable of disintegrating steel.

Kamal Obeid, S.E., Structural Engineer

Kamal Obeid is a licensed structural engineer who practices in the San Francisco Bay area. He has nearly 40 years of experience under his belt. Obeid's questions surrounding 9/11 began shortly after the event, when he volunteered to join the U.S. Federal Emergency Management Agency (FEMA) team responsible for investigating the incident. Although he didn't end up on that squad, Obeid's search for plausible answers from the FEMA and NIST researchers/investigators continues to this day.

Obeid began his career as a civil engineer in the 1980s, working on large public works structures such as dams, power houses, and power facilities. After receiving his structural engineering license from the State of California, he began his own firm. One of his specialties is the analyses of steel-framed buildings. Specifically, he evaluates whether they require seismic retrofits due to their earthquake-prone setting.

A structural engineer is responsible for the “nuts and bolts” of any significant construction project. It is his responsibility to take the design of the architect and ensure that every column and beam and their connections are able to sustain the load requirements. Types of loads that structural engineers evaluate include wind loads, seismic loads, and horizontal and vertical structural loads.

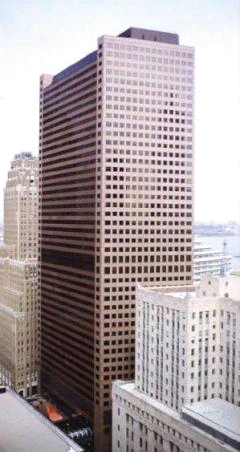

For Obeid, the focal point of his skepticism is the explanation given for WTC 7's collapse and the removal of debris, which precluded a sound forensic investigation. In the years that followed the 9/11 attack, he had the opportunity to review the structural blueprints for WTC 7 and could not reconcile the official explanation of the collapse with the building's design and composition.

“I find the collapse story for WTC 7 strange,” he said. “Most of the debris was immediately cleared away and the material was not properly examined. NIST's entire theory is based on a computer model that they created and not upon actual evidence from the scene. What further bothers me is that no one raised an eyebrow, not a peep, over the fact that the steel was removed from the site and sent to China on barges for recycling starting just two weeks after the collapse.”

“I find the collapse story for WTC 7 strange,” he said. “Most of the debris was immediately cleared away and the material was not properly examined. NIST's entire theory is based on a computer model that they created and not upon actual evidence from the scene. What further bothers me is that no one raised an eyebrow, not a peep, over the fact that the steel was removed from the site and sent to China on barges for recycling starting just two weeks after the collapse.”

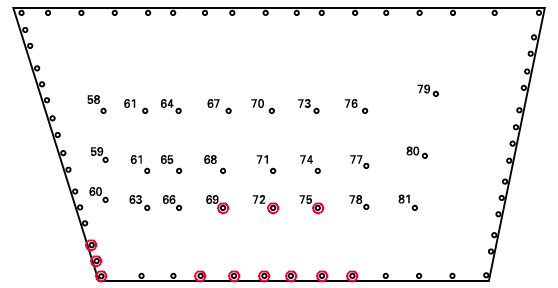

Obeid studied WTC 7's collapse from a structural standpoint: “The theories in the NIST report were flawed. The sequence, as demonstrated in their computer model, indicates that one girder was pushed off of its seat on the supporting column, which commenced the failure sequence. That then led to a progressive collapse near the corner of the building, which then, they say, dragged the entire building down — and that happens symmetrically into its own footprint!”

Having had the opportunity to review WTC 7’s blueprints as a structural engineer, Obeid cites specifics as to why the official cascading failure story doesn't offer adequate explanation.

“WTC 7 was constructed with a double-tubular design, where the exterior was made of a latticework of steel columns, steel beams. Inside this tube of steel was another tube of similar construction, designed to work together with the exterior tube to resist the lateral loads. This combination tube system makes it near impossible to have this building collapse at near free-fall acceleration into its own footprint — which it did — especially from a localized collapse in one portion of the exterior tube.”

“WTC 7 was constructed with a double-tubular design, where the exterior was made of a latticework of steel columns, steel beams. Inside this tube of steel was another tube of similar construction, designed to work together with the exterior tube to resist the lateral loads. This combination tube system makes it near impossible to have this building collapse at near free-fall acceleration into its own footprint — which it did — especially from a localized collapse in one portion of the exterior tube.”

Of NIST's computer model of the WTC 7 failure, Obeid observes: “If you look at the animation put out by NIST, the model crumples up like a soda can and in no way resembles the actual footage of WTC 7's collapse. The animation stops after only two seconds — well before the actual video of the building's seven-second collapse is finished. So we do not get a full accounting of the collapse from initiation to completion. I've read expert reports on the collapse by other structural engineers regarding the NIST explanation, and I found that in each case the scope of their discussions are so limited, so circumscribed, that they're really useless as far as analysis is concerned. Not one structural engineer discusses the whole story, or how this 'perfect storm' of circumstances came to pass.

“Also,” Obeid continues, “the fire story doesn't check out. The photos reveal that the fires had already burned out, more than an hour before the collapse, at the floor where NIST claimed that [the fires] were responsible for the thermal expansion that started the collapse. And while it's not impossible to have a localized structural steel failure due to fire, they could not produce a total collapse at near free-fall acceleration. That is impossible.”

Help Enlist Others in the Call

If you have friends who are part of the scientific community or the building trades industry — or who are simply members of the public who want the truth about 9/11 to come out — share our evidence with them and urge them to sign the petition at AE911Truth.org.

Show them our 15-minute Solving the Mystery of Building 7 video, hosted by Ed Asner. Send them a free PDF of our booklet, Beyond Misinformation: What Science Says About the Destruction of Towers 1, 2, and 7 of the World Trade Center. And hand them our concise evidence brochure.

Only by educating fellow citizens and encouraging them to speak out about the evidence can we further erode the wall of silence that surrounds this monumental issue. By bringing the truth of 9/11 to light, we can do our part in making America and our world more honest, just, free, and fair to all.